NSF awards $449,973 to ASU researcher’s work to better bioengineer bone tissue

An Alabama State University (ASU) researcher has received a $449,973 National Science Foundation (NSF) grant to better understand how to bioengineer bone tissues.

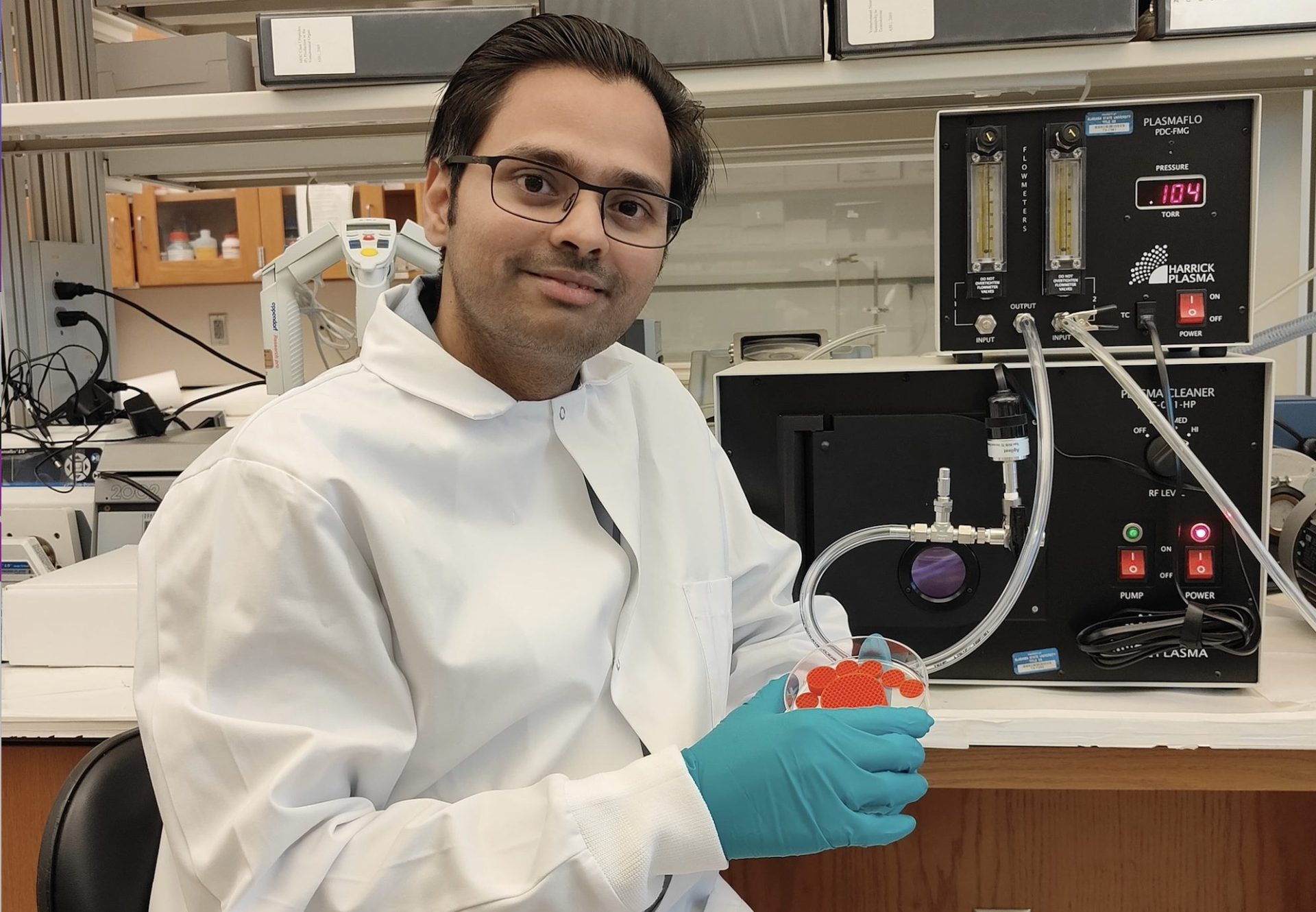

Dr. Vineeth Viijayan, assistant professor of biomedical engineering, will study the safety and functional performance of nanoparticle-modified 3D printed polymeric biomaterials for tissue engineering applications. The new research will continue the work he began with $40,000 in seed funding from Connecting the Plasma Universe to Plasma Technology in Alabama: The Science and Technology of Low-Temperature Plasma (CPU2AL) in 2020.

CPU2AL was the NSF Established Program to Stimulate Competitive Research (EPSCoR) predecessor grant to the current $20 million NSF EPSCoR Future Technologies & enabling Plasma Processes (FTPP) plasma science and engineering grant, both managed by The University of Alabama in Huntsville. An Alabama coalition of nine universities and a research corporation, FTPP aims to transition plasma research into commercial applications, establishing Alabama as a Southeastern regional hub for plasma science expertise.

“When comes to tissue engineering applications or any other biomedical application, it is very critical to reliably study the safety and functional performance of materials before proceeding to animal experimentation and clinical studies,” says Dr. Viijayan.

“Nanoparticle-modified 3D printed scaffolds are highly important for applications like bone tissue engineering, owing to their osteogenic or bone tissue forming potential. However, the production of nanoparticle-modified 3D printed polymers has challenges such as multiple steps, toxicity concerns, scalability and batch-to-batch variability.”

A new platform Dr. Viijayan is developing looks promising to solve the issue with the production of nanoparticle-modified 3D printed polymers and can test the material and biological responses reliably.

“This thought process has resulted in an approach of marrying or combining low-temperature plasma-assisted nanoparticle production methods with 3D printing of polymers,” he says.

what is plasma?

A state of matter consisting of a collection of ionized particles, electrically neutral atoms and molecules, plasma makes up more than 90% of the observable universe and underpins several high-tech manufacturing industries.

“Plasma is one of the safest, and one of the greener, methods employed to modify the surface of biomaterials,” says Dr. Viijayan.

Two low-temperature plasma-based nanoparticle deposition processes he developed in previous research will be used to deposit gold and silica nanoparticles on the surface of different 3D-printed polymer scaffolds that can then be used to grow cellular tissues.

“I have successfully produced and anchored silica, gold and silver nanoparticles on the surface of 3D-printed polylactic acid scaffolds using the seed grant project from CPU2AL,” he says. “After joining Alabama State University, I continued and expanded the research of plasma-assisted nanoparticle production and development of new scaffold designs with high-throughput potential.”

Dr. Viijayan will investigate the bone-forming capability of the gold and silica nanoparticle-modified polymers on a large-scale using bone marrow-derived mesenchymal stem cells and studying their responses.

“This can provide new insights into the relationship between the material properties of nanoparticle-modified polymers and their bone-forming potential,” he says. “It can positively impact the clinical success rate of polymer-nanoparticle hybrid materials for applications like bone tissue engineering.”

Reliable screening

Commercially, the research combining 3D printing and nanotechnology can contribute to reliable high-throughput screening of the safety and osteogenic differentiation potential of gold and silica nanoparticle-modified 3D printed scaffolds.

“This can improve in vitro approaches and maximize the success rate of further in vivo testing of nanoparticle-modified biomaterials, saving time and overall expenses related to preclinical studies,” says Dr. Viijayan.

“Also, another promising commercial aspect of this work is that other researchers working on nanoparticle-modified scaffolds for tissue engineering can potentially use these new scaffold designs with high throughput screening potential for reliably studying in vitro testing before proceeding to the costly in vivo and clinical studies.”

Working with Dr. Viijayan is Dr. Derrick Dean, professor and program director of the Department of Biomedical and Mechanical Engineering, who serves as the co-principal investigator. Dr Dean will contribute to the 3D printing of high-resolution polycaprolactone, polylactic acid, and polyether ketone scaffolds in the project.

FTPP collaborating institution researchers Dr. Vinoy Thomas and Dr. Yogesh Vohra at the University of Alabama at Birmingham (UAB), Dr. Ed Thomas at Auburn University and other collaborators at UAB helped and supported Dr. Viijayan in obtaining seed funding from CPU2AL in 2020.

The work that originated from the seed grant was further expanded with support from ASU’s biomedical engineering program and the faculty research award from ASU’s Office of the Provost and Vice President for Academic Affairs, helping to secure the present NSF grant.

“One of the biggest advantages of being a part of the CPU2AL consortium was the opportunity to collaborate with all these individuals from various departments and more importantly, the financial support provided to me in the form of a seed research grant from CPU2AL which supported my independent research work at UAB,” Dr. Viijayan says.

engineering training

An important aspect of the project is providing advanced research training to the engineering students at ASU, a Historically Black College and University, in areas such as additive manufacturing, plasma surface modification and nanotechnology, says Dr. Viijayan.

The grant will train one postdoctoral fellow and seven undergraduate students in the biomedical engineering program for three years, as well as conducting public outreach activities that showcase research activities related to 3D printing, plasma surface engineering and nanotechnology.

“A societal impact provided by the project will be the training of underrepresented African-American engineers in advanced areas of research,” he says. “This can significantly contribute to increasing the representation of skillful engineers from the underrepresented population. Also, the outreach activities planned in the grant can contribute to increased scientific curiosity and awareness among the public community in Alabama.”